HM-ZD600 Automatic Rigid Box Making Machine- Product Overview

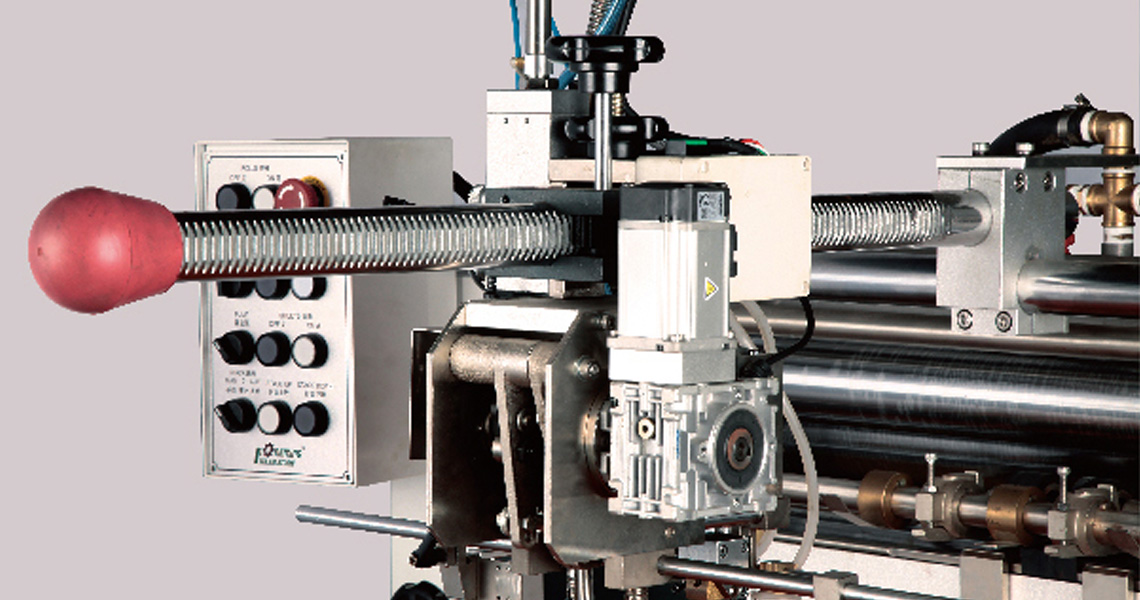

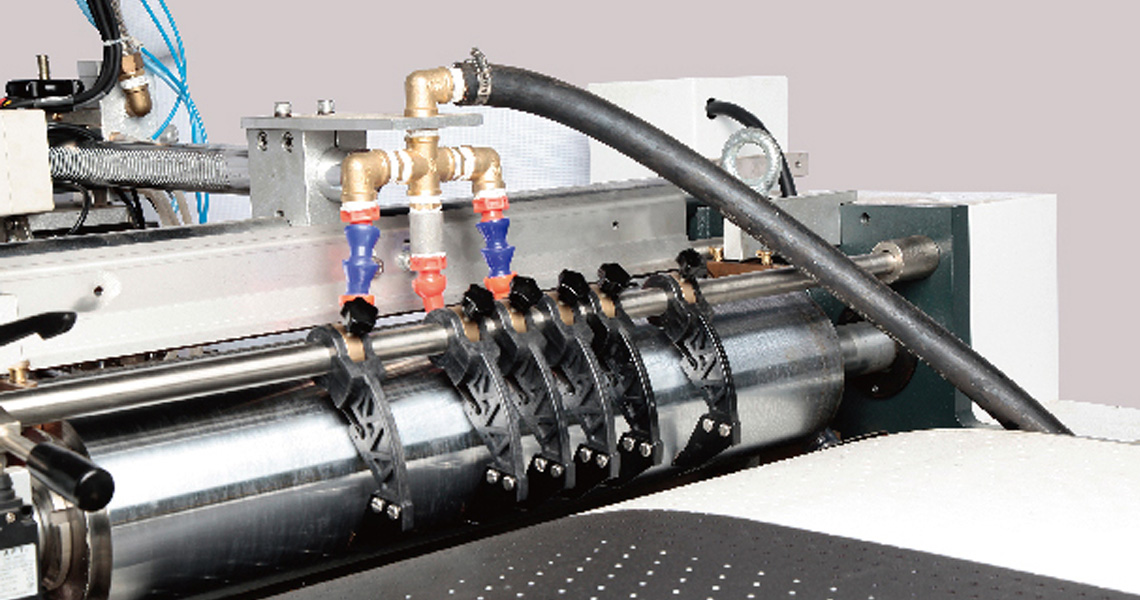

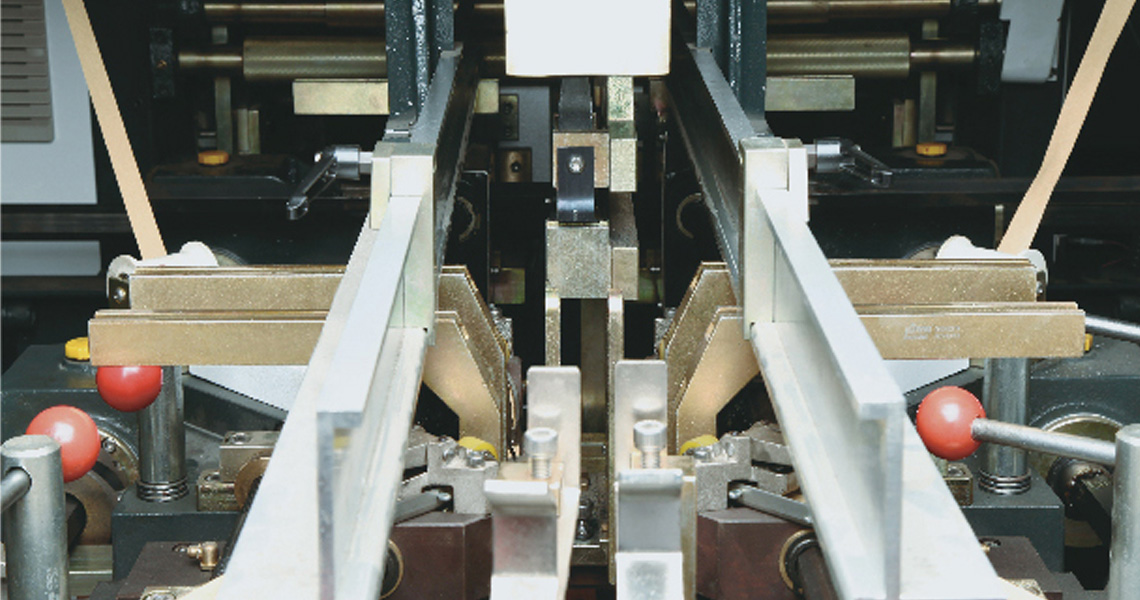

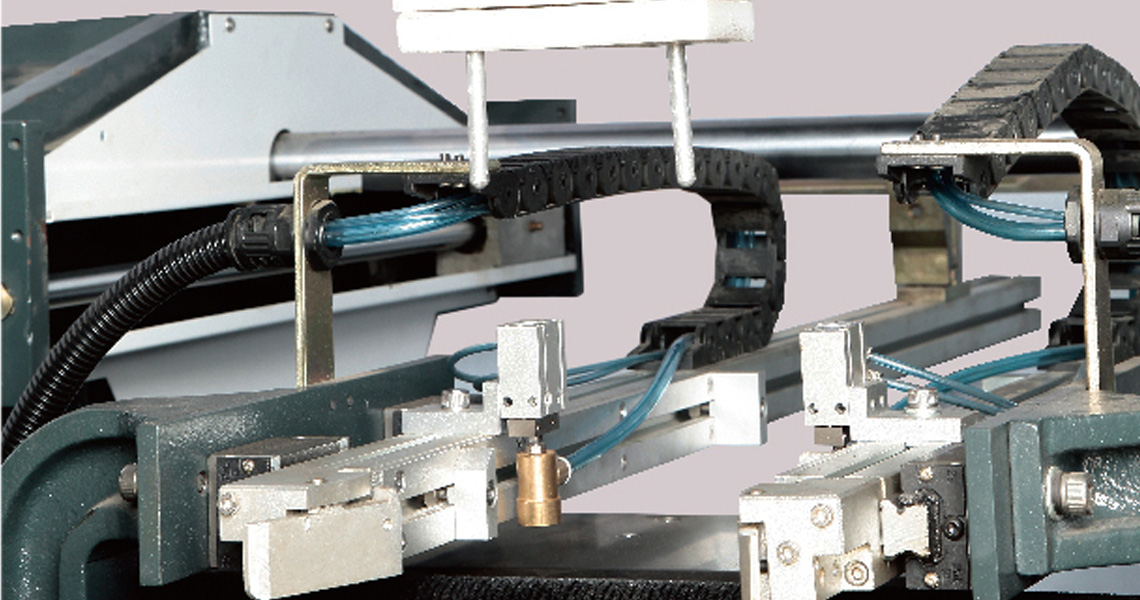

Features

form boxes in one process.

fold corner edge, fold in and form box.

Technical Specifications

| Model | HM-ZD600 | |

|---|---|---|

| Paper Sheet Size (B=Length, A=Width) |

B (Max.) | 850mm |

| B (Min.) | 180mm | |

| A (Max.) | 610mm | |

| A (Min.) | 95mm | |

| Finished Box Size (L=Length, W=Width, H=Height) |

L (Max.) | 600mm |

| L (Min.) | 125mm | |

| W (Max.) | 400mm | |

| W (Min.) | 50mm | |

| H (Max.) | 130mm | |

| H (Min.) | 12mm | |

| Greyboard Thickness (T) | T (Max.) | 3mm |

| T (Min.) | 1.0mm | |

| Paper Thickness | Thickness Range | 80-160gsm |

| Folding Edge size (R) | 15-45mm | |

| Corner Edge Size | 10-16mm | |

| Paper Pile Height (Max.) | 300mm | |

| Greyboard Pile Height (Max.) | 850mm | |

| Glue Tank Volume | 40L | |

| Air Supply | 350L/min, 0.8Mpa | |

| Speed | ≤30pcs/min | |

| Voltage | AC380V | |

| Heating Power | 4kW | |

| Power | 13kW | |

| Net Weight | 5800kg | |

| Machine Dimension | 6800mmx4500mmx3300mm | |