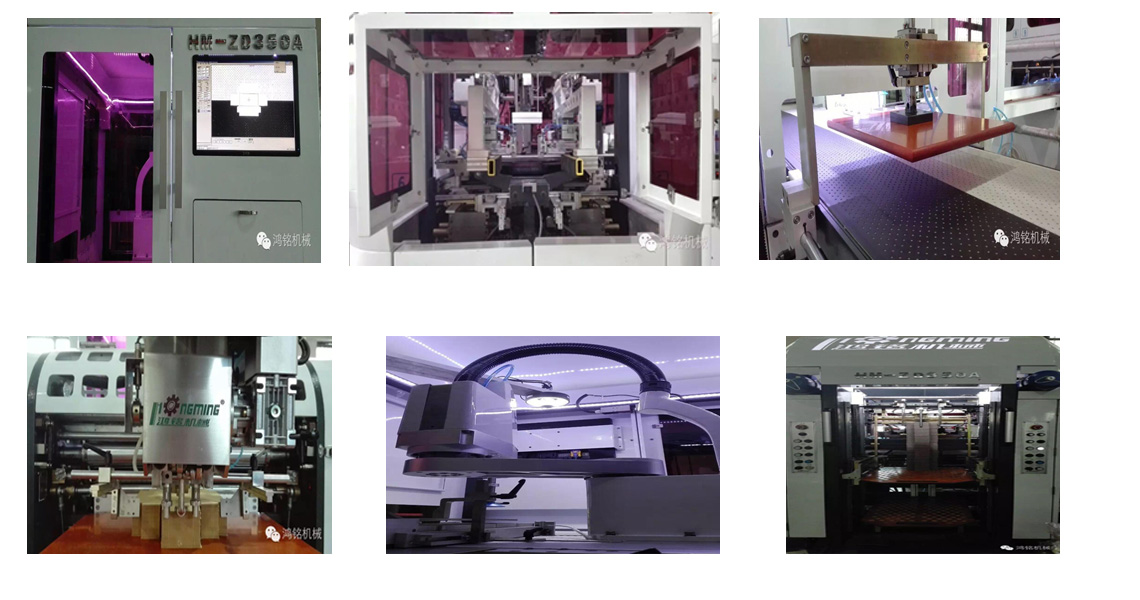

HM-350A Automatic Rigid Box Making Machine- Product Overview

Features

(four corners), with independent man-machine control

±0.3mm)

edge, fold in and form box.

Technical Specifications

| Model | HM-350A | |

|---|---|---|

| Paper Sheet Size (B=Length, A=Width) |

B (Max.) | 600mm |

| B (Min.) | 110mm | |

| A (Max.) | 455mm | |

| A (Min.) | 45mm | |

| Finished Box Size (L=Length, W=Width, H=Height) |

L (Max.) | 350mm |

| L (Min.) | 45mm | |

| W (Max.) | 250mm | |

| W (Min.) | 35mm | |

| H (Max.) | 120mm | |

| H (Min.) | 10mm | |

| Greyboard Thickness (T) | T | 1-3mm |

| Paper Thickness | Thickness Range | 80-160gsm |

| Folding-in Depth (R) | R | 8-80mm |

| Paper Corner Edge (E) | E | 8-80mm |

| Paper Pile Height (Max.) | 300mm | |

| Greyboard Pile Height (Max.) | 850mm | |

| Glue Tank Volume | 20L | |

| Air Supply | 480L/min, 0.8Mpa | |

| Speed | ≤32pcs/min | |

| Voltage | AC380V | |

| Power | 23kW | |

| Net Weight | 4200kg | |

| Machine Dimension | 5500mmx4500mmx3000mm | |